All About Suppository Molds

and Packaging

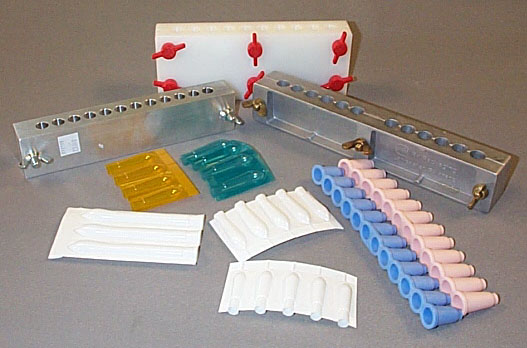

Aluminum

metal molds come in a variety of cavity sizes and with a variety of number of

cavities per mold. Common sizes vary from 1 g to 2.5 g, and common number of

cavities range from 6 cavities up to 100 cavities. The two halves of the mold

are held together with either nuts or some molds have 1 centered screw.

Aluminum

metal molds come in a variety of cavity sizes and with a variety of number of

cavities per mold. Common sizes vary from 1 g to 2.5 g, and common number of

cavities range from 6 cavities up to 100 cavities. The two halves of the mold

are held together with either nuts or some molds have 1 centered screw.

Plastic

suppository shells come in long strips that can be torn into any number of cavities.

The suppository mixture is poured directly into the shell up to a mark. These

disposable molds do not need any lubrication regardless of the suppository mixture.

When the mixture has hardened, the plastic mold is heat sealed. When a patient

is ready to use a suppository, they select one shell and peel the sides of the

shell off to obtain the suppository. One advantage of this type of mold is that

if the suppository should melt, it will not run out of the mold. If the material

can ongeals again, it will retain the suppository shape. This type of mold is

available in 1 g to 5 g sizes, and many different colors.

Plastic

suppository shells come in long strips that can be torn into any number of cavities.

The suppository mixture is poured directly into the shell up to a mark. These

disposable molds do not need any lubrication regardless of the suppository mixture.

When the mixture has hardened, the plastic mold is heat sealed. When a patient

is ready to use a suppository, they select one shell and peel the sides of the

shell off to obtain the suppository. One advantage of this type of mold is that

if the suppository should melt, it will not run out of the mold. If the material

can ongeals again, it will retain the suppository shape. This type of mold is

available in 1 g to 5 g sizes, and many different colors.

There are also suppository molds made from flexible rubber. When the suppository

mixture has congealed in these molds, the finished suppositories are "pushed"

out of each cavity. If the prescription does not require all of the cavities

in the strip, it can be trimmed with scissors. These flexible rubber molds are

ideal if the suppositories need to be refrigerated (shells also are suitable

for this purpose).

There are also suppository molds made from flexible rubber. When the suppository

mixture has congealed in these molds, the finished suppositories are "pushed"

out of each cavity. If the prescription does not require all of the cavities

in the strip, it can be trimmed with scissors. These flexible rubber molds are

ideal if the suppositories need to be refrigerated (shells also are suitable

for this purpose).

Very

hard rubber molds are similar to the metal molds in that they have screws to

hold the mold together. When the suppository mixture has congealed, the screws

loosened, and the suppositories are removed. This photograph is a picture of

an urethral mold. If you enlarge the image, you can see PEG suppositories in

one side of the mold. Such thin suppositories require a great deal of investigation

to get the desired consistency and strength. If the suppositories are too soft,

it is very difficult to remove them from the mold. This particular casting had

70% PEG 3350 and 30% PEG 400.

Very

hard rubber molds are similar to the metal molds in that they have screws to

hold the mold together. When the suppository mixture has congealed, the screws

loosened, and the suppositories are removed. This photograph is a picture of

an urethral mold. If you enlarge the image, you can see PEG suppositories in

one side of the mold. Such thin suppositories require a great deal of investigation

to get the desired consistency and strength. If the suppositories are too soft,

it is very difficult to remove them from the mold. This particular casting had

70% PEG 3350 and 30% PEG 400.

Pouring and Opening Suppository Molds

Molds should be filled only when they are at room temperature. A cold or frozen

mold should never be used because it can cause fractures and fissures throughout

the suppository. Each cavity should be filled slowly and carefully ensuring

that no air bubbles are entrapped in the cavity. To prevent layering in the

suppositories, the pouring process should not be stopped until all the cavities

have been filled. Molds should be allowed to set at room temperature. Refrigeration

should only be used if the suppository has not congealed after 30 to 40 minutes.

Aluminum molds usually require lubrication before use. Hard rubber molds may

require lubrication. One way is to use a vegetable oil spray. Other lubricants

include light mineral oil when water soluble bases are being used and glycerin

or propylene glycol when oleaginous bases are being used. Whatever lubricant

is used, only a light coating is needed. If too much lubricant is used, the

excess will pool in the tip of the suppository cavity. Any excess lubricant

should be wiped off with an absorbant tissue such as a Kimwipe.

When suppository mixtures and bases cool, they contract. Some mixtures and

bases have very pronounced contractions (e.g., cocoa butter, PEG) while others

have much smaller ones (e.g., glycerinated gelatin, MBK®). This contraction

will produce a hole in the open end of the suppository. Such a hole is undesirable.

If the suppository mixture is poured just immediately

before it reaches its congealing temperature, the contraction will be

minimized. It is also helpful to pour a small excess of the suppository mixture

on top of the open end of the mold.

When filling a suppository mold, start pouring the melt at one end and pour

continuously without stopping. Don't go to the next cavity until the previous

cavity is filled and a slight excess has been poured to overfill the cavity.

Excess base can be removed once the suppositories have congealed by trimming

the top of the mold with a warm stainless steel spatula.

Suppositories shells are generally poured using a back light to help visualize

the mark on the shell. Some molds (depending on the size or type of the suppository)

cannot be poured, but the mixture is added using a syringe.

Examples of each of these pouring (or filling techniques) are given.

When

the suppository mixture has congealed, the excess mass is removed from the top

surface of the mold and the mold is separated into the two halves. An efficient

way to separate the mold is to remove the wing nuts or loosen the centered screw

and place the mold so that the posts rest on the table top. Then apply a downward

pressure only on the bottom half of the mold. A knife or spatula should not

be used to pry the two halves apart. This will damage the matching mold faces

which have been accurately machined to give a tight seal. (See Opening a Mold)

Suppository shells can be opened by peeling the halves apart if this type

of shell is used. There are suppository shells that do not peel apart at the

bottom but must be torned along its edge. These are very difficult to open,

and should not be used.

View a video demonstration on using a metal

suppository mold

Suppositories

that are not in a plastic shell mold or flexible rubber mold should be wrapped

before they are dispensed. This will provide protection for the suppository

and limit any oil staining that might occur from the materials contained in

the suppository base.

Once

the suppositories are wrapped, they are generally placed in a special box that

has dividers for each suppository.

Once

the suppositories are wrapped, they are generally placed in a special box that

has dividers for each suppository.

Flexible

rubber molds can be packaged with the suppository still in the mold. Generally

the mold is placed in a special box.

Flexible

rubber molds can be packaged with the suppository still in the mold. Generally

the mold is placed in a special box.

Plastic shell molds must be heat-sealed. Heat

sealing is generally a two step process. First the open end of the shell is

"shrunk" with the aid of heat. A hair dryer (at highest hot setting)

is capable of providing enough heat to shrink the plastic. There are labatory

type hot air "guns" that also can be used. The heat will cause the

two sides of the opening to collapse together and begin to seal the opening.

The second step is to use an electric sealer to completely seal the opening.

View a video demonstration on filling and

heat-sealing suppository shells